Manufacturing & Production

OM Paktek employs multiple advanced plastic processing technologies to manufacture reliable and application‑specific packaging solutions. Each process is selected based on product design, strength requirements, and functional performance.

Injection Moulding

Our injection moulding process is designed to deliver high‑precision, dimensionally accurate packaging solutions with consistent quality across large production volumes. Supported by controlled parameters and in‑house tooling, this process enables the manufacture of complex packaging formats with excellent repeatability for performance‑critical industrial applications, using machines ranging from 80 to 150 tons capacity.

Blow Moulding

Our blow moulding process is optimised for the production of uniform, hollow packaging solutions with consistent wall thickness and structural integrity. Controlled processing ensures reliable shape accuracy and durability, making it suitable for high‑volume industrial packaging requirements, with a production capacity of up to 80,000 pieces per day. Our customised blow moulding machines support a machine capacity ranging from 50 ml to 5 litres, enabling precise and flexible packaging production.

Deep Moulding

Deep moulding allows us to develop flexible and cost‑effective packaging formats with faster turnaround and design adaptability. This process supports both simple and complex forms while enabling efficient prototyping and scalable production based on application needs.

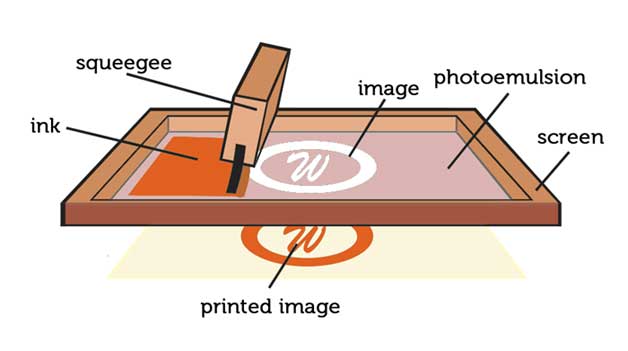

Screen Printing

Our screen printing process ensures clear, durable, and long‑lasting branding on plastic packaging surfaces. With controlled ink application and colour consistency, this method supports precise product identification and professional visual presentation.

Extrusion Moulding

Extrusion moulding enables the production of continuous plastic profiles with consistent cross‑sections and dimensional stability. This controlled process supports uniform output and flexibility in cutting, finishing, and application‑specific customisation. Our extrusion machines support a diameter capacity ranging from 7 mm to 200 mm, allowing precise and reliable profile manufacturing across varied applications.